Camper VO70 - the nuts and bolts

This article follows on from our interview with Marcelino Botin and Chris Nicholson published on Wednesday.

Australian Neil Cox came on to the radar as boat captain of ABN AMRO Two during the 2005-6 Volvo Ocean Race, moving on to running shore operations for Puma during the last fully crewed round the world race, a job he has continued for Emirates Team New Zealand’s Camper campaign.

With skipper Chris Nicholson, Cox from the outset was integral to some of the fundamental decision-making over the Kiwi team's new VO70. “We thought there were massive performance gains to be made by just basic yacht design that hadn’t been tapped into, so it was a case of ‘let’s re-evaluate the box’ - everything from VCG to why does the freeboard need to be this big, to why does the deck need to be so cambered - material, windage, VCG, etc," he says. "Some of them were gains of a small percentage, but if you take them together they add up. A lot of thought went into every detail. The biggest thing was just trying to make the boat clean.”

As usual with Emirates Team New Zealand boats, Camper was built by Mick Cookson in Auckland but, interestingly, unlike the Juan K designs which are fully carbon-Nomex, Camper has a foam core in the slamming areas. Cox has fond memories of having to replace a large section of the bows areas on the ABN AMRO boats when they were in Cape Town back in 2005.

There is some superb build detailing like the rule-compliant foredeck hatch, a flush-fitting circular carbon fibre affair built by Cookson (“one of New Zealand’s little treasures” as Cox describes him) and offset to port, but of a minimum size, so it doesn’t look like it will see too much action other than for ventilation purposes. Cox says that in his experience foredeck hatches typically leak and become water traps.

Camper's forestay tower, used to gain J length, is modest compared to the giants on the Farr and Juan K designs. “It is a small gain but it is another piece of the puzzle,” says Cox. Similarly the bowsprit has been angled slightly downward to gain luff length for the kites, although as Cox warns, drop it too low and the helmsman can’t see the end of it.

Like all of the new VO70s, Camper’s gunwhale from the mast forward is cut-off. The reason for this Cox says is that it is a bit lighter (one side of a triangle, instead of two), plus it is better for windage and controlling the way spray comes off the boat.

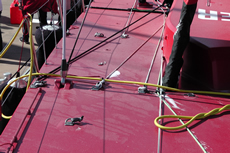

The mast is of course from Southern Spars, as is Telefonica’s, but on Camper the four sets of spreaders are in-line rather than swept back. All the standing rigging is Southern’s EC6, bundles of carbon fibre 2mm protruded rods, but with a braided Spectra cover over it. Attached to the front of the mast is the radome which navigator Will Oxley tells us houses a standard radar antenna rather than a more modern ‘broadband’ one, which allegedly offer massive performance improvements, plus lower power consumption.

We don’t touch upon the issue of strops and adjustable forestays, but Cox says that the tack lines for the headsails are controlled by rope purchases going back to cockpit winches for reasons of weight and simplicity. “The worst thing that can go wrong is a piece of rope. We can always splice in a piece of rope or change a dog bone, etc.”

However there are hydraulics for standard sail functions such as the outhaul, Cunningham, upper checkstays, jib car, etc. Cox says that Camper has more hydraulics than they had on Puma last time and part of the reason for this came from crewman Stu Bannatyne’s experience on Ericsson 4, the hydraulics allowing for more grunty control while the weight of some of the rams can be included as part of the rig weight.

Camper’s cabin top appears to be nothing special compared to how it integrates with the curvy deck on Abu Dhabi Ocean Racing or the deck bulge in Telefonica, however Cox says that when they were putting the boat together they left the cabin top off until quite late in the build, making it easier with the fit-out down below. The deck, inside of the cabin top, forms the bottom of the halyard tunnels running down either side.

As described yesterday, Camper’s most unique feature is the relative fore and aft positioning of her mast, keel and daggerboards. One advantage of having the daggerboards adjacent to the mast is that the uphaul lines for the boards can be taken off the mast, as they were on ABN AMRO Two.

“The bearings we have got are great,” continues Cox on the topic of the boards. “One of the things you try improve is how your boards go up and down under load, etc. We had a pretty good system last time with Puma and with a high load bearing we were able to get the boards to go up and down quite well. This is the next evolution.” He adds that their engineer Giovanni Belgrano also made a “quantum leap” in the engineering of the asymmetric boards and the tooling required for their build at Cooksons.

As on most VO70s, the majority of the control lines for the headsail fairleads operate through a block and tackle arrangement, the blocks attached to padeyes. On Camper the exception is for their biggest jib where there are tracks either side of the aft end of the cockpit (mounted on the cockpit bulkhead).

Camper's cockpit differs from the other VO70s in having her mainsheet pedestal aft of the mainsheet track. As usual immediately forward of the main sheet track there is a central island for the mainsheet winch with a control panel for the hydraulics on the aft side of this. The winch/pedestal package is from Harken. Running forward on each side is the 990 traveller winch, then a smaller Harken 50.2 winches for the traveller, which are also used to sheet the staysails, then the 1111 primaries and then finally the pit winches, where there are two to starboard and one to port.

On the transom, inboard of where the emergency rudders can be fitted, are two plungers used to expel the 1.6 tonnes of water ballast that can be brought on board into the tank fitted between the transom and aft bulkhead. Camper haven’t gone for an elevated sheeting position for the big kites on the aft quarters, seen on some boats, while their runners attach at the top of the transom by the strut running between the transom to the top of the topsides (the deck terminating just forward of the helming positions).

Cox says that one of the most significant changes this time around have been the limitations on where it is permitted and not permitted to stack. Specifically the stack cannot be shifted aft so that it covers the liftraft and you are no longer able to stack behind the aft bulkhead down below and the stack also cannot extend beyond the transom or outside the perimeter of the deck.

“That was a performance punch in the guts,” states Cox succinctly. “All of a sudden from being able to get 1.5 tonnes of gear in the back corner with the sails on top of them to the rule change – how are we going to get that control of the boat back? Every little bit counts in terms of getting it low and aft. That was one of the biggest things in the rule change.”

To make the most of the stack, the stanchions are angled outward, off the vertical by the maximum of 10 degrees permitted in rule 4.7.8. This allows the stack to be positioned around 50-60mm further outboard. “Again in the grand scale it is a miniscule percentage, but it all adds up,” says Cox.

There are few load cells actively used while sailing. Cox says there is one in the bowsprit and there are load cell pins for the J4. “The mainsheet trimmer has access to a lot of the loads. It is amazing the information with the different pages you can bring up on the B&G with the GFDs as opposed to the FFDs.”

Down below most noticeable is that the pipecots extend all the way forward to the main bulkhead (rather than the more usual position at the cockpit bulkhead) with stacking bins below. Having the bunks forward leaves a large area where it is possible to stack as far aft as is now allowed in the rule. It may also be relevant to Camper's centre of buoyance being further forward than normal.

The majority of living area down below is also painted – again now mandatory in the rules. “Compared to ABN AMRO One it has just a vastly different mood. It does illuminate inside and it masks it easier to clean. It is purely to get video footage - you are not sticking a camera into a dark cave,” says Cox.

During the development of Camper they built a mock-up of the cockpit, but also the complex structural area down below around the keel/daggerboards/mast, comprising two partial bulkheads and one full bulkhead. “Mick machined up various sections of the boat, we stood them up inside the loft there and we kept playing around it,” says Cox. “We had four different configurations of what would happen with the daggerboard cases up to ring frame C, etc and every one of them had merit, what was going to work best structurally and functionality for getting sails through the boat and what was ergonomically friendly. Primarily our biggest concentration was to make sure we had a structurally sound set-up and there was no movement, just to try and lock everything in.”

Up forward are the galley and head and Cox says that otherwise the bow area isn’t used apart from occasional light air stacking.

Aft, navigator Will Oxley has a tackable nav station that allows him to sit up to weather when working his magic while their media crewman Hamish Hooper will operate from the standard-sized media desk further aft. Some of the ‘furniture’ in this area isn’t locked into the hull as Cox points out that there are certain areas in the boat which are more vulnerable to slamming and so they don’t want these to be integral to the yacht’s structure.

Another change to the rule this time around is that boats must have a prop shaft that retracts within the hull. Thus a more efficient fixed 550mm three bladed propeller is now used, instead of the folding prop fitted to boats in the last race. According to Cox this requires a longer prop shaft being fitted, although he points out that this, along with the media desk and the windage-heavy antennae tower above the transom, represent performance hits that all the teams have to take.

As usual with a Team New Zealand boat, the crew have become extremely competent at sailing their new steed. With at least 11,000 miles under their keel they have probably sailed more miles than any other team, without any major breakage, despite the majority of these miles having been upwind in big conditions. As skipper Chris Nicholson puts it: “The boat has been to Armageddon and back but it is sailed pretty well. The guys aren’t in the habit of trying to smash it to pieces. There is a smart way to sail these boats in 40 knots upwind.”

Click on images to enlarge them

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in