Horatio Carabelli on Telefonica's hull damage

Telefonica was the only one of the three Juan Kouyoumdjian-designed VO70s competing in this Volvo Ocean Race to suffer structural problems to her hull on leg five.

“Basically one of the front panels suffered delamination of one of the skins. It was the skin and also a partial shear of the core, about 3m forward of the mast on the bottom,” explains Telefonica’s Shore Team Manager, Horatio Carabelli, of the damage that occurred to the Spanish VO70 while battling through the Pacific section of the Southern Ocean.

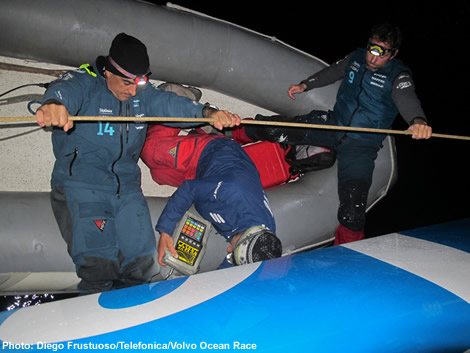

At the time, the team carried out a running repair using sail battens to stabilise the damaged panel. “We made several suggestions of how to do it,” says Carabelli. “They needed to slow down, because with Sikaflex, when the panel is moving, you just can’t fix anything. So some mainsail battens were glued to the panel to stabilise it to keep it from moving and making it worse.”

At the time, the team carried out a running repair using sail battens to stabilise the damaged panel. “We made several suggestions of how to do it,” says Carabelli. “They needed to slow down, because with Sikaflex, when the panel is moving, you just can’t fix anything. So some mainsail battens were glued to the panel to stabilise it to keep it from moving and making it worse.”

Meanwhile the shore crew prepared a 2.3m x 0.6m sized panel in a CNC-machined female mould that would fit on to the inner skin, to help ensure that the VO70 made it to Brazil without further incident. Due to transporting this to Ushuaia and then on by boat to a cove to leeward of Herschel Island, just north of Cape Horn, the panel also had to be cut into sections. Once Carabelli had been united with the crew, they had the panel fitted in 10 hours and had to wait another five hours for the resin to cure.

Upon arriving in Itajai, close to Carabelli’s home town of Florianopolis, this temporary beefing up of the panel was taken off and, over the course of 10 days the Spanish VO70 was out of the water in Itajai, the damaged panel was replaced and the boat successfully remeasured.

The exact reasons for the failure, Carabelli say, are hard to determine. However on this leg the boats did experience some very sharp seas: “Off the coast of Auckland, beating upwind where Abu Dhabi had the J4 [bulkhead] failure - there the guys said it was really really tough. So maybe you have an issue there. Then along the road, I know they dropped off a big wave while doing 35-40 knots of speed. And you need to take care of these boats. There was a moment of the race where we gained a lot on the others. So I think the facts speak for themselves...”

Carabelli confirms the point made by Ian Walker that in big conditions it can be difficult to sail a VO70 below 15 knots and it can also be unsafe doing so. “Sometime it is safer to go with a little more speed. But there is a limit – the big question is where.”

According to Carabelli the structure within Telefonica's hull has been very well engineered by Juan K’s team. “They have link skins, so if you have a delamination of this kind, then it stops the propagation. So that is pretty cool and then you don’t have a huge panel delaminating.”

The core material throughout the hull is Kevlar Nomex, with the exception of a few localised areas where foam core is used. Kevlar Nomex, Carabelli says, has superior shear properties over standard honeycomb core.

The mid-Pacific incident was the first Telefonica has experienced in this race that has caused her to slow down. Carabelli says it might have been possible to sail on to Itajai without stopping, if the conditions had allowed, but they didn’t because they weren't. “The engineering has been great otherwise. Apart from that there’s been nothing else.”

As to the breakages more generally across the Volvo Ocean Race boats on leg five, Carabelli attributes this to the boats being pushed harder than ever before, in what is an ever more competitive fleet. “There are five teams who can be at the top and then you can really push. If you don’t push, then you are not at the limit...”

As to the rigging failures that have occurred and caused the dismastings, Carabelli says they have had no issues with their package from Southern Spars, including the EC6 carbon fibre rigging. Over the other carbon fibre rigging products being used in the race, EC6 has the advantage of having had more miles put on it than any of the newer alternatives. “We went around with it last time on Ericsson 4, so we were confident with it,” says Carabelli, who aside from being a yacht designer by trade, has also competed in the last two Volvo Ocean Races, on Brasil 1 and then on Torben Grael’s winning Ericsson 4.

He continues: “I think specifically the rigging failures are down to the lack of testing. All this new solid carbon rigging offshore - it is the first time that it is going around. We tested it in our program and we didn’t have the confidence to have enough time to accept it.”

As to the furore over the widespread damage to the boats in this race, if you take the rigging issues and resultant dismastings out of the equation, then the carnage to date has been less than occurred in the last race when the fleet was struck down between Singapore and Qingdao in the last Volvo Ocean Race.

“If you compare this to the last race, that was the same level or even worse actually,” says Carabelli. “Ericsson 3 had a big failure and had to change 6sqm of panels. They hit something and Delta Lloyd, the second time around the world, had this issue. And Telefonica Black – she nearly broke in half. So I think Volvo have moved forward. This time around, all the boats had to be ISO-compliant [ie their structure]. That was not the case last time when the teams got away with ABS where there is much less structure involved. So it has stepped up and everyone has moved forward on the safety side. Plus we use Kevlar honeycomb cores and that is also another step on the safety side...”

However Carabelli warns that build quality in a VO70 is vital and this cannot be rushed - potentially a problem for teams late to secure their funding and start their builds. “If the conditions in the race are easy, then they will be okay, but when the conditions get really really hard, as was the case here... We had a lot of upwind, much more than the last race. The percentage has been higher and in heavy, heavy seas. So it is quite demanding for the boats. Definitely it is not an upwind boat – a 70 footer that is 17-8 tonnes fully loaded, it is like a skiff, and a skiff is not designed to go upwind. Every time these boats go upwind, they suffer. And when they go downwind they go at 30 knots with 40 knot peak speeds. So when you drop from a 10m wave at 40 knots, it is quite a dynamic load, and sometime you could be over what is within the rule itself even.”

As a yacht designer, Carabelli is not overly keen on the prospect of the next Volvo Ocean Race being sailed in one designs – one option currently under investigation by the organisers.

“We like the development and that is the reason why we are here: to develop your own tools and gear and that also makes the difference. It depends on the way you look at it. By being one design, the boats will break as well, if you don’t sail them properly. But I believe that Volvo is really trying to reduce costs. Going one design, it could be a way of doing that as the boat will cost much less than these boats. But at the end of the day, you will still have to build them pretty similarly.”

But in the big picture, the boat is only a part of Volvo Ocean Race campaign cost, as Carabelli observes: “The other one is logistics – there are nine stopovers, so reduce that to six, then you reduce quite a lot of money, rather than looking at the boat itself. And if you see the amount of money we are paying to get our containers from Abu Dhabi to Brazil or from China to Auckland – the figures are unbelievable. There is much more money involved there than looking at the boat itself."

Latest Comments

Add a comment - Members log in