Ker goes Class40

The Class40 is entering a new phase this year with a deluge of new boats being launched. One of the most interesting is from Jason Ker, representing the British designer’s first foray into shorthanded offshore race boats.

Ker’s 40 One Design project is being bankrolled by Team Concise’s Tony Lawson, who has been involved in the class almost from the outset. Last year Lawson came close to throwing in the towel with Class40 due to the debacle over the Sam Manuard-designed Mach 40 being allowed an adjustable forestay. Lawson felt this was strongly indicative of the escalating costs in the class and plain wrong.

As Ned Collier Wakefield, Lawson’s skipper and project manager for the 40 One Design, observes, the first Concise they owned, an Akilaria 1, cost them 159,000 Euros, while their current Akilaria RC2 cost around 275,000 Euros, but the price tag for latest generation boats like the Mach 40 or the new Verdier or VPLP designs is around 450,000 (less sails and electronics) – a significant leap in six years. These kinds of price hike are making it increasingly hard for private owners to remain competitive in the class.

Thankfully adjustable forestays are now outlawed. While Joerg Riechers’ Mach 40 mare.de won the Solidaire du Chocolat last year's, it was generally agreed in the class that this was more due to the German skipper simply sailing smarter. In turn Lawson is back in the class and on a trip to see McConaghy in China over another project, started contemplating his own Class40 one design. Collier Wakefield says they liked Jason Ker’s IRC designs and British designer already works closely with McConaghy in China, where the Ker 40 and 46 are built.

The philosophy of the 40 One Design is for it to be competitive with the latest generation Class40s, but at a price just above that of racing spec production Class40s such as the Akilarias and the Pogos made by Structures.

The price of the 40 One Design is set to be 300,000 Euros (ex sails, electronics, running rigging, shipping and tax), a fraction more than the racing versions of the Pogo and Akilaria, but will have a higher spec as standard - built in epoxy, optimised rudder stocks, a high strength steel fin, etc.

Escalating prices of course come as no surprise in a development class, as boats get more complicated to build and designers start seriously addressing issues such as lowering VCG, in turn demanding higher build standards. As Collier Wakefield puts it: “Originally the class ethos was ‘fierce racing, friendly class’ and that was taken quite literally. Now it all about pushing the boundaries as hard as you can.”

This being Ker’s first stab at an offshore boat, they have put months of work into the design and some aspects of this process have been ground breaking. Key to this is using ‘neural network’ software, the use of which for yacht optimisation Ker says they have been developing over several years. This effectively is a step towards an artificial intelligence way of designing. “It is a mathematical concept that is modelled on the human brain, so it basically is able to learn the combined relationship of a lot of different effects,” says Ker. Neural networks can be trained to recognise patterns and in the real world are used from anything between predicting movement of stocks and shares to optical recognition.

Jason Ker (left) with Simon Schofield

In practice the Ker office took the design data of a number of Class40s and ran the CFD for these on their in-house computer cluster. “A large quantity of high quality data has to be produced in order to sufficiently feed the neural network, which is only possible to do with a highly automated system. We use Numeca's excellent FINE/Marine RANS CFD system (also used by Team New Zealand) which we have adapted to our exact needs with many automation scripts enabling high throughput with minimal human interaction required,” says Ker.

Around 10-20 parameters were then fed into the neural network and used to look at optimum drag and stability characteristics. Obviously a neural network is strongly fallible to bullshit in-bullshit out, but Ker says they verified the data as they went: the best results from the initial run through the neural network were fed back into the CFD, the numbers crunched again before being used to retrain the neural network.

The neural network generates a huge amount of data therefore they have developed an evaluation program to examine this, with the best results subsequently fed into additional software to calculate the polars for each boat and in turn how these relate to the anticipated weather conditions for the races the boat is destined for.

At present Ker reckons that probably the only other people using a neural network for yacht design at a similar level are Oracle Team USA, as Dr Andrew Mason put them on to it some years back and he’s now working for them.

“The conventional way yacht designers work is to start with a hull shape they think is fastest and then they try pulling parameters and seeing if it is a little bit faster or if it is slower they will go the other way, etc. Essentially it is a slow iterative process that only explores a tiny part of the design space. Once a neural network is trained and has learned the correlations, it’ll tell you in a thousandth of a second the drag associated with a given set of parameters, so you can short cut the process, cover the whole of the design space if you need to, learn all of the possible relationships between all of the parameters, and then you can ask it a million times over if you feel it necessary – effectively you scatter gun it with a lot of different possibilities and eventually you find some that are good.”

In developing the 40 One Design, Ker’s neural network churned through more than 70,000 hulls and in the end they went for hull number 56,528...

A more comprehensive article on this process is set to appear in the next issue of Seahorse (Andrew Hurst, you owe us beer...)

The upshot is that the 40 One Design is a powerful reaching boat, which Ker describes as ‘well optimised but not radical.” It is of course a significant departure from designing boats for windward-leewards and Ker says this involves more compromises between areas of the performance envelope, where again the neural network helped establish the optimum. However Class40 are also more complex with additional sailing configurations, whether the 750kg of water ballast is in or not and how the boat is stacked, etc.

The 40 One Design has several interesting features. A new Class40 rule prevents new designs having a scow bow, like David Raison’s Mini Transat winner, by having a station 200mm back from the bow where the beam cannot exceed 450mm. The 40 One Design is around 5mm below this, although this volume doesn’t extend down to the waterline - typically while the beam is wide, the waterline is narrow. Freeboard is also lower than is for the Ker 40, but Ker says that there is more volume directly beneath the side of the boat, ie more slab-sided compared to the flared topsides on his IRC boats.

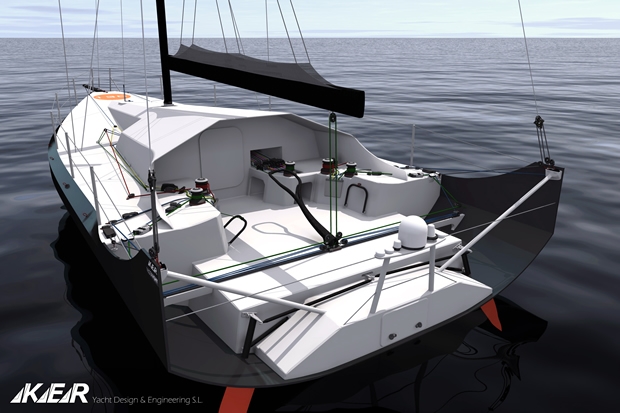

Perhaps most unusual is the stern which features VO70-style raised chainplates (known in Volvo circles as ‘batwings’) for the runners/spinnaker turning block and a cockpit that ends short of the transom.

The raised chainplate provides a better angle for the runners when using Code 0s and makes spinnakers believe they are being used on a bigger boat. “The higher you can get your sheeting point, the more range you can get out of each sail and the more evenly you can trim your sails through different wind angles,” says Ker. “If the sheeting point is too low, you get far too much twist at the wide end of the sails’ wind angle range.” In addition the batwings raise the sheerline in this area, helping the boat comply with the Class40’s 90deg inversion test.

Located aft of where the cockpit finishes are the rudders. These feature a kick-up mechanism, similar to that found on the PRB IMOCA 60.

The rudders are very high aspect, as on the Akilaria, Collier Wakefield says, they often experienced excessive leeway. Ker adds: “We thought there is not a lot of point of skimping on the depth of the rudders if they are kick-up. The only downside of this is that the rules require you to make the stocks out of steel so they end up heavier but we have gone to some lengths to make sure that the stocks are light as they can be, while being stronger than they need tobe.”

Ned Collier Wakefield (left) with Sam Goodchild

According to Ker ending the cockpit short of the transom allows a more efficient position to stack sails aft and is also presumably lower windage. The lack of deck in this area also helps the boats right during the mandatory 180° inversion tests Cat0 boats are put through. Meanwhile the ‘chamfer’, ie the cutaway gunnel (at last we have a name for it!) helps in the Class40 90° test where boats when inclined must show positive stability representing 235-320kg at the masthead (the aim is to hit the maximum end of this limit). This seems to be a good rule, according to Ker, because it reduces the drive towards the absolute limit in weight saving.

Important to passing the 180° rule is also the size and shape of the cabintop and the 40 One Design has hers extending forward of the mast, with a step in allowing a 6° sheeting angle for the jibs. In this step each side is a PRB-style forward facing window.

Structurally the boat is also different, featuring a ‘keel tower’ (as used in the AC V5 boats) where effectively the top of the keel foil extends up to the deck. This, plus the use of 30mm instead of 20mm fore core in the hull and substantial longitudinals, is primarily to avoid having any lateral structure in the middle of the boat, thus enabling sails to be moved fore and aft unimpeded.

The keel tower effectively moves the structure for the keel to a vertical beam rather than a horizontal one, but that same beam is also then used to support the mast step at the deck. The natural horizontal deck structure is triangulated by a ‘V strap’, diagonal rods extending from the chainplates down to the keel head, that the sails can be dragged under when the boat is heeled. Combining the structure for the mast and keel in this way represents a weight saving and despite the structure being moved to the deck, Ker says that the overall VCG remains lower, especially when considering that the bulb remains further to windward while sailing.

In developing the sail plan, Ker and his team worked (and are still working) with Chris Williams of North Sails Design Services. During this project Ker’s team developed new ‘sail morphing technology’ to analyse the efficiency of different sailplans through their trimming range, again using the neural network to learn the relationships, but to keep their in-house compute cluster free for hydrodynamic calculations, they used the Wolfson Units Super-computer facility at Southampton University. “Our new system allows us to morph sails through many different shapes and learn the effect of those shapes on heeling moment, driving force, etc and therefore create a sail model that we can use in our VPP.”

The rig has yet to be finalised but it will probably have three swept back spreaders. “We have been at pains to make sure the rig will be well balanced through as wide a range of reefing positions as possible, because that is the biggest advantage of an inclinable rig. But we are keeping it simple,” says Ker.

The sail plan is likely to feature a relatively big mainsail and a small jib on a fixed forestay, utilising the Code 0 for sailing upwind in light conditions.

Class40s can carry 750kg of water ballast each side. The 40 One Design has a single tank each side, which is long in order to get the weight further outboard. The tanks drain directly aft and interestingly have no transfer pipe as typically around 80kg of water usually sits in this. While a transfer pipe might be welcome on short course races (one wonders if one could be retrofitted) this shouldn’t be an issue on long distance races, Ker reckons.

Single tanks means there is no ability to use water ballast to adjust fore and aft trim, done solely by moving the stack and the sails.

The cockpit layout appears fairly standard with the cabintop extending aft to provide some protection. There won’t be a sliding coachroof but they will have two wings extending aft from the sides of the cabintop to redirect the deluge of green water charging aft. They are also developing a helming bubble that clips on to the weather wing and which they will be able to tack. “It’s not great for windage, but when you’re racing it protects your face a little bit and allows you to be on the helm as much as you can,” says Ned Collier Wakefield.

Lines pass aft from the mast back to the pit area in cockpit via a tunnel that is offset to starboard with the companionway hatch to port. There’s a single pit winch and the offset primary will be used for the halyard when reefing/unreefing. While halyard locks are prohibited by the class, locks on the reef lines aren’t (probably an omission in the rule) and these are likely to be used on board. For the singlehander these are useful, maintains Ker’s business partner Simon Schofield. “When you pull it in, it locks off in the boom and then you know you have the outboard end set in the right place. There is no messing around trying to get the reef line tension correct.”

Build of the 40 One Design, as mentioned, is taking place at McConaghy in China and, according to Schofield, the secret to keeping the price down, without compromising the design or the materials used, is in making it simple to build. “Everything is flanged in, there is no secondary bonding, it all drops in very quickly to keep the hours down, which doesn’t add weight it just requires some skill of the builder. I don’t think there is anything we would change in the specification if we were asked to do a custom boat.”

The boat is designed to fulfil both Cat 1 (for the transatlantic races) and Cat 0 for the Global Ocean Race. The latter requires an additional bulkhead to be fitted but this is easily done with the mast bulkhead filled by an extra panel simply bolted in place.

The 40 One Design is expected to be a weapon reaching but will also have reasonable upwind potential. The VPP is currently indicating that its VMG upwind will be faster than that of the Ker 40 (which weighs 4.8 tonnes compared to the Class 40’s 4.5) in the higher end of the wind range, though requiring an notably fast-low mode.

The first 40 Open Design is due into the UK mid-July and if it can be worked up in time it will compete in the Rolex Fastnet Race, before Collier Wakefield teams up once again with Sam Goodchild for the Transat Jacques Vabre. The following year, that boat will either be sailed singlehanded by Collier Wakefield in the Global Ocean Race or in the Route du Rhum, most likely the former. “My ultimate goal is to do a Vendee, so I see that as one of the most affordable way to get experience racing around the world singlehanded,” says Collier Wakefield.

Latest Comments

Soundsail88 22/01/2013 - 04:19

Nat Herreshoff would love it because it's fast. Reliance was regarded as "ugly" in her day.381394 21/01/2013 - 10:34

Not sure what Nathaniel Herreshoff would make of that shearline. I guess if its a rocket ship then it will be the new beautiful just like F1.Add a comment - Members log in