Under the skin of the new Alegre

In these chaste times, the Mini Maxi fleet continues to hold steady with six boats competing this week at the Maxi Yacht Rolex Cup in Porto Cervo. Absent is Sir Peter Ogden’s elongated Judel Vrolijk 60 Jethou (due to the owner having conflicting family commitments), but fighting it out off the Costa Smerelda are the trio of Judel Vrolijk 72s, Niklas Zennstrom’s Rán 2, Italian Alessandro Rombelli’s Stig and defending World Champion Hap Fauth’s Bella Mente, plus Alexander Schaerer’s Mills 68 Caol Ila R and George Sakellaris’s Reichel Pugh 72 Shockwave. Much news is afoot in the class with the Jethou team in the process of acquiring Stig and a new Rán, another design from Judel-Vrolijk, currently in build at Persico in Italy, with a second boat looking set to come off Rán’s moulds for a German owner.

However the present new kid on the block at the Mini Maxi Worlds (that forms part of the Maxi Yacht Rolex Cup) is the latest Alegre, a Mills 72 once again for US/Philippines-based owner, Andrés Soriano.

Like Bella Mente, which was launched last year, the new Alegre is a second generation Mini Maxi, the team’s first Mills 68 now sold to Alexander Schaerer, for whom it won this year’s Rolex Volcano Race.

For the latest boat Soriano returned to Ireland-based American designer, Mark Mills (right). In fact ‘returned’ is not entirely accurate for they never really parted company – within the Alegre team several key players, including Mills and long term sailmaker, North UK’s Kevin George, have been continually involved with the campaign. In this and several other aspects, the set-up of the Alegre team resembles a Cup campaign.

For the latest boat Soriano returned to Ireland-based American designer, Mark Mills (right). In fact ‘returned’ is not entirely accurate for they never really parted company – within the Alegre team several key players, including Mills and long term sailmaker, North UK’s Kevin George, have been continually involved with the campaign. In this and several other aspects, the set-up of the Alegre team resembles a Cup campaign.

For example the team operates out of the giant Victory Challenge base in Valencia, where they have been rattling around only slightly – with a crew of 22, which often trains out of the former Port America’s Cup when the team is not competing, plus the shore crew and support staff such as Mills - the Alegre chef finds himself regularly catering for more than 30 people. They have also acquired as their support ship the massive 63ft long uber-RIB, famously the Alinghi tender from the 2007 America’s Cup. They use this as other teams use containers, to cart their gear between regattas (it has been re-proped now its days of towing Version 5 boats are over).

In the Mini Maxi fleet, the first Alegre was known for having the narrowest waterline for her length and as a result proved a weapon in light-medium conditions. The new boat has been optimised similarly. Designer Mark Mills explains: “A fundamental key of the first Alegre was it being very strong in light-medium. That separated us from the rest of the fleet and gave us an edge, not only in those conditions, but it also allowed us to get off the start line better - with more fin area on a light airs-orientated boat, you end up with more height as an option. In a fleet, as you see in the TPs, the first leg counts for a disproportionate amount of the race value, so that ended up giving us some benefit that Andy [Soriano] wanted to see continued on into the second boat. So the combination of Andy’s stated aims and the weather model – coughed out that as a result.”

Alegre’s Project Manager, Olly Cameron points out that they wanted to retain their edge in around 12 knots, as in stronger conditions performance comes down more to how the crew sails the boat.

Also significant, compared to the last boat, is that the new Alegre has been optimised principally for the International Maxi Association’s Mini Maxi inshore circuit, with her only offshore races likely to be the Rolex Middle Sea Race and the Rolex Giraglia Cup. So they have hit this corner of the performance envelope much harder. Mills explains: “The 68 was intended to be able to do all sorts of things - offshores, inshores, deliveries transatlantic and have a minimum interior standard – so there was a galley and all sorts of things in it. Racing inshore for the last four seasons made it clear that a) the boat didn’t need to do a lot of those things and b) they involved compromises that a really competitive inshore boat wouldn’t accept.”

The weather study for the new boat benefitted from already having four years worth of weather data logged on these courses from the first boat. However the owner was also keen to invest in the R&D program for the campaign, not just in financial terms, but in time too. The green light for the boat was pressed in December 2011 with hull lines having to be provided to her builder, Longitud Cero, located near Castellon, north of Valencia (where most of the Botin TP52s have been built) by June 2012.

To carry out the study the team employed the services of Valencia-based KND–SailingPerformance and its three principals - Cyrille Douillet (ex OneWorld, Areva, Telefonica, Groupama), Roland Kleiter (ex Judel-Vrolijk, illbruck Challenge, United Internet Team Germany) and Dimitri Nicolopoulos (ex Areva Challenge, Quantum Racing, Safran). From the R&D on the weather model, they subsequently carried out much of the CFD work prior during the design process.

KND and Mills were key members of Alegre’s design team that also included winch designer Jon Williams of Stayinphase, engineer Steve Koopman of SDK Structures, sailmaker Kevin George, Kevin Batten at Southern Spars, Andy Soriano’s representative David Williams, project manager Olly Cameron and Ximo Lopez from Longitude Cero.

Since the boat has been launched, KND, like Mills, remains part of the team, handling the performance analysis. The advantage of having them on board full time says Mills is that it “closes the loop. They do the performance at the front end, the VPP and CFD work, but also the performance analysis of log data at the back end. Being able to put those two different jobs into one group’s hands is a very powerful tool.”

While the weather study showed Alegre’s anticipated racing conditions to be principally light-medium, the polar curves for these also showed a lobe at the higher end of the wind range due to the sea breeze in Palma and typical conditions (although not this week) in Porto Cervo. However Mills says that they were happy following the experience of the first boat “to focus on the lower lobe and manage the upper one.” Nonetheless, the new Alegre does have a beamier hull shape compared to her predecessor. “I think we were very competitive in a breeze with the previous boat and we will be a lot closer to ideal in those conditions now," says Mills.

In finalising a hull shape they tested around 40 hulls divided roughly into two families of hull shape. One of these came out of the work designers carried out on the AC90 proposal for the 33rd America’s Cup, that has subsequently been seen in boats such as the Botin TP52s. Mills explains: “They have a flat central portion at the transom and then a bit of flare out to very powerful shoulders - incredible performance upwind in a breeze. Especially that first Botin 52 for Team New Zealand - upwind, it was multiple tenths of a second faster than it is competitors. But it is weak in light airs and not as fast VMG running as you’d think with that amount of flat surface at the back.”

The alternative was the more traditional hull shapes of boats such as the Judel Vrolijk 52s, with a less powerful chine, more flare and a relatively narrow flat run along the centre line. “That was the path of mainstream yacht design up until this AC90-type alternative showed up,” says Mills. And this was the path they followed with the new Alegre. The hull is less powerful than the AC90 type, but compared to the Judel-Vrolijk Mini Maxis, Alegre’s hull has more flare and slightly more power with mild chines, or ‘inflexions’ as Mills calls them. “There is a little turn that will help on a reach, but without the drag negative of a chine washing along in a draggy way. Bella Mente has a not dissimilar feature.”

In addition to having a maximum length of 72ft, Mini Maxis race under IRC, something that since last year the class has committed to for five years. “IRC does a fantastic job at larger boat sizes in terms allowing progressive, fast fun boats to be built that are rewarding to sail. There is a very little compromise involved from a design side,” says Mills.

72ft Mini Maxis are typically in the 17 tonne range, which seems heavy compared to say a VO70 which is 14, however Mills points out that the added weight is because the boats are for windward-leewards (and less so for reaching), with, as mentioned, the opening beats being vital. “We looked at a spread of displacements. You could do a Mini Maxi as low as 16.25 tonnes under IRC and be able to do a good job, but it just wasn’t the right answer for this particular solution.”

The displacement is also there to get a favourable rating under IRC. As Olly Cameron (right) observes: “You are looking to be heavy, but you obviously want to have the option of having the weight in your bulb. At the big end, IRC can be an expensive rule if you want to push it. For example there is no sail limit – you can build a brand new set of sails for every regatta.”

The displacement is also there to get a favourable rating under IRC. As Olly Cameron (right) observes: “You are looking to be heavy, but you obviously want to have the option of having the weight in your bulb. At the big end, IRC can be an expensive rule if you want to push it. For example there is no sail limit – you can build a brand new set of sails for every regatta.”

If Bella Mente is supposedly the beamiest at the waterline in the Mini Maxi fleet, the new Alegre is at the narrower end. However Mills says that they haven’t followed the present trend for powerful bows with substantial volume in the topsides forward. “We looked at that, but we couldn’t make it pay. While volume has increased at the waterline we were happy to keep relatively less bulbous topsides. Andy’s interest was to also partially make sure the boat looked attractive and had some connection with his previous boat.”

In terms of keels, one of the most significant developments has been the move from milled to fabricated fins. These are now looked on more favourably by IRC, says Mills. This has resulted in a slightly thicker chord-length ratio, however in terms of bulb shape, fin area and its T-shaped configuration, Mills says they are middle of the road with Alegre. The bulb has a shortish overall length to minimise wetted surface at the expense of frontal area – similar to the Judel-Vrolijk boats.

Engineering

Probably the most significant steps forward the new Alegre has made, involve her engineering. For this the team worked with Steve Koopman at SDK Structures in Rhode Island, but there was also great input from the rest of the design team, especially from Ximo Lopez of boat builder Longitude Cero.

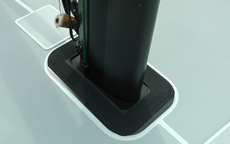

In particular great lengths have been gone to linking deck and hull beyond merely the bulkwarks and the bulkheads, by creating a structural ‘web’ throughout the boat. So there is a keel tower extending the loads from the keel head up to the deck, while there is a ‘V-strap’ conversely taking the loads from the chainplates down to the keel – something Lopez pushed for. This arrangement was used on some of the Version 5 Cup boats and has since featured on several Botin Partners TP52s.

“It is really increasing the stiffness at the keel interface with the hull,” continues Mills. While on some Version 5 boats the fin extended all the way to the deck, Alegre instead has a substantial composite post bolted on to the top of the fin and this instead extends up to the deck. The arrangement looks like it should add weight but this is more than balanced by the reduction in structure around keel on the cabin sole.

Olly Cameron adds: “It is similar to the Cup boats, but because we have swept back spreaders we couldn’t do the floating foot. It is halfway there.”

In addition beneath the primary and runner winches there are ‘pods’ that again serve to share loads between deck and hull, further tying the two together (a similar arrangement to the Farr-designed Abu Dhabi VO70). These pods are effectively carbon fibre cones extending from beneath each winch, down to the hull. However they are also used as a convenient place to house and mount gear and bevel boxes.

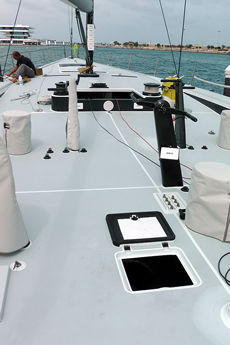

But most obviously unusual about the new Alegre is her deck, where the foredeck ramps down to the cockpit sole, rather than there being a more conventional step. We’re thinking ‘good for skateboarding’, but apparently the less generous refer to it as ‘good for wheel chair access’.

There are a multitude of advantages to this arrangement. It is better structurally. The conventional step at the cockpit bulkhead structurally represents two 90deg hinges, which the ramp eliminates.

Also it makes faster access between cockpit and foredeck. As Olly Cameron says: “It is easier for getting the sails up and down and off the bow and for packing headsails as well, because you can just drag them back and you can flake a headsail no problem, even if you can have a furling sail sitting on the side deck.”

But there are further implications too – the sidedecks' sole now are as crew hiking benches. Hence they are narrow and extend aft to the transom. Olly Cameron explains: “You sail these boats with so people – 22 crew is a massive number of people to get across the boat during manoeuvres. We felt that with this set-up you can get off the rail and get back out on the rail really quickly, which was important.”

Between the deck ramp, the keel tower and V-strap and the winch pods, the structural stiffness of Alegre for her weight is unparallelled. “We are looking at headstay sag numbers far lower than we would have in the past,” advises Mills.

A downside one would presume from the deck ram would be that Alegre has the opposite of a ‘well protected cockpit’, funnelling water directly aft. However to date it has worked out well. Instead of green water being launched at the hard working crew at chest/waist height, it washes through at ankle height instead, which is much safer. It also causes water to fall down to leeward sooner.

As Cameron says: “We thought ‘it is going to be soaking wet’, but, in fact, it is drier than the conventional deck on the old boat. The water just seems to shed. And where it does come down it goes straight out of the back. And the other thing is that we’ve set this boat up for cross sheeting, so the spinnaker is being trimmed on the windward side all of the time, so the trimmer is not down to leeward.”

The very open cockpit arrangement and turning the cabin top and pit area effectively into an 'island' has caused a few issues. However Olly Cameron came up with the solution of having the pitmen work from the ‘Admiral’s’ position, on the companionway steps. “We saw what Bella Mente did with their offset pit and we disagreed with that, because we believe it is a two person job and you have to have room for them,” he says.

Operating out of the Victory Challenge base, the Swedish Version 5 boat was still located there with no obvious future. The boat had been sailed in anger for only five weeks during 2007 before being mothballed with all her gear intact. So the Alegre team bought her electronics, hydraulics, winches and containers full of spares. While some was traded in for newer gear, the winches made it on board: all apart from a counter-rotating 65 come from the Swedish Cup boat.

As with many of the Mini Maxis, the layout of the winches and grinders was designed by Jon Williams of Stayinphase, whose pedestals are fitted to the boat. The set-up also involved the integrating rotary pumps for the hydraulics and powering the take-down line for the kites.

So in terms of the winches, what can Alegre do that other Mini Maxis can’t? “I believe we are the only one with both pit winches driven, and that adds value in terms of getting around corners and completing operations simultaneously,” says Mills.

Cameron adds: “When you want to get a furler up, getting the tack line tension that you want is a big wind with a top handle. Your left hand winch usually ends up doing that, so we wanted to make that driven so that we could get the tack down quickly.”

Kite sheets are sucked out of the way down below on to the latest version of Diverse’s Reeler system. However there are a few other novelties for managing the kite sheets, including below deck clutches that can be flicked off with trigger lines.

The arrangement of the take-down line on Alegre is also different compared to the other Mini Maxis. As usual there is a roller on the underside of the deck on the aft side of the foredeck hatch. This is slightly angled to port, so the take-down line can run aft down the port side of the boat’s interior and then immediately forward to its drum, mounted on the outboard side of the pod beneath the port primary.

The cockpit, winch and pedestal set-up, plus the narrow ‘sidedecks’, were mocked up at full scale at Longitude Cero to see how they would operate with the boat heeled at 25 degrees.

Hydraulics

Cariboni has been responsible for the hydraulics. These, Olly Cameron says have been taken a bit further than on other Mini Maxis. “We have gone for hydraulic tacks on staysails and things like that, whereas the other boats have got 2:1 purchases with a jammer. If we go offshore we put the ram in and if we are racing inshore we take them out. We just felt that if you go to the hassle of putting a lock in the rig you want a tack ram to deal with it.”

One of the most exciting parts is that Alegre has full mast butt movement under sailing load. “That is about 47 tonnes of compression when we are going upwind,” says Cameron. “The noise is pretty scary as the rig gets pumped backwards and forwards.”

Cariboni also made the lifting leg for the engine. Rather than being metal, the pipework for the hydraulics is made in plastic, braided with carbon fibre (as is fitted to Stig). According to Cameron Alegre’s entire pipework weighs something like just 5kg total.

On the hydraulic manifold, every function is fitted with a pressure sensor, that is logged together with all the other data.

Alegre is believed to be one of the first race boats to be fitted with braided carbon fibre steering cables, supplied by Future Fibres. Another nice feature is the carbon fibre exhaust pipe that is laminated to the underside of the cockpit sole.

Back on deck, at the top of the ramp either side of the mast are the ring/fairleads for the headsail sheets. These have the track hidden below deck like the Botin TP52s have, only that here the up/down and inboard/outboard controls for positioning the ring are controlled by hydraulics. The chainplates are set up in the modern way, hidden below deck with waterproof covers over them. The stanchions – titanium of course – are from West Engineering, while the blocks are from WinMar Racing (which works with Emirates Team New Zealand and Luna Rossa), made in titanium with ceramic bearings. All the ropework has been done by Mark Thomas of TT Rigging.

With Alegre’s rig, Mills says that they didn’t want to break new barriers. Saying that the three spreader mast supplied was Southern Spars’ first Mini Maxi spar to be built using their TPT technology. All the locks are from Southern.

The sail wardrobe was put together by Kevin George. Again R&D budget was allocated to this, with the team spending some time in the University of Auckland’s twisted flow tank. The resultant inventory includes a furling jib top, but the boat is also unusual in having different inshore and offshore bowsprits. According to Cameron one of the issues with the set-up on the VO70s was that when they did peels between furling sails, the furling drums on the bowsprit used to hit each other. On Alegre the furlers have enough separation at the end of the bowsprit to avoid this, while there is also a third tack line going out to the bowsprit.

Alegre is set up with a VSPARS system (allowing video of the sail and rig set-up to be recorded with a time code that allows it to be viewed alongside output from the performance instruments, load cells, etc). This was set up by crewman Simon Fisher with the help of eminent navigator Will Best.

Down below is pure stripped out race boat – much more so than the first Alegre. The only compromise is that she has a proper enclosed head compartment, to cater for the owner’s guests, but, built in carbon fibre (including the head itself), it weighs nothing. Similarly, the galley, if it can be described as such, is merely a carbon fibre hoop with a couple of jet boils slung off it (and this can be tacked from side to side).

One nice feature is that in addition to the main companionway, there is a small secondary hatch aft in the cockpit sole. Typically when racing they put a storage bag under it, making it a handy place to stash binoculars, handheld VHFs, etc, while at the dock it provides light to the back of the bus and allows air to flow through.

The new Alegre’s crew is even more of an all-star cast than it was before including Gerry Mitchell on mainsail (he sailed with Andres Soriano when they campaigned the Alegre Soto 40 last year), Richard Sydenham, plus Tom McWilliam trimming, Volvo Ocean Race sailors Phil Harmer, Andy Meiklejohn and Chris Main, with Matt Cornwell on bow.

From the Maxi Yacht Rolex Cup, Alegre heads to Malta for the Rolex Middle Sea Race.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in