Rebirth of the 100 footers

A new chapter in the 100ft maxi story began this year with the launch of the first WallyCento, Charles Dunstone’s Hamilton. A second of the new breed, Sir Lindsay Owen Jones’ new Magic Carpet, is currently in build at Wally’s facility in Ancona due for launch in March in time for PalmaVela in April.

Hamilton was built by Green Marine in Hythe to a design by Judel-Vrolijk in accordance with both the ‘Wally rule’ and also the ‘WallyCento’ rule. The former details the philosophy of Wally, while the latter is a box rule defining the shape of the WallyCento itself – such as 30-30.48m LOA, 6.5-7.2m beam, a bow overhang of 0.2m, a lifting keel of 6.2m max draft, weight of 45-50 tonnes and of course the principle rig dimensions. Read more about this here...

Generally the idea is to end up with a boat that is not dissimilar in concept to Mike Slade’s newly refitted ICAP Leopard – essentially a luxury ‘designer’ yacht with all modcons that can be used for cruising, but which is otherwise a pure race boat. In displacement terms this means the new Hamilton is lighter than a typical Wally 100 such as Indio, which weighs 59 tonnes, but around twice the displacement of the spindly Reichel Pugh 100 pure racers like Wild Oats XI or Esimit Europa 2.

Owner Charles Dunstone is no stranger to the maxi class. While there is a larger 117ft Hamilton superyacht, he previously campaigned the 77ft Nokia Enigma. This he sold after a successful season in 2003 when he won both the Rolex Fastnet Race and the Middle Sea Race. However inshore racing is what Dunstone prefers and prior to the arrival of his new boat he campaigned his IRCed TP52s Rio.

James Stagg, who project managed the build along with Richard Clampett, explains how Hamilton came about: “They had talked about a 100 footer and Magic Carpet had wanted to do a 100 footer for a while. Charles ultimately wanted to sail against other Wally owners, he wanted to join the class. He knew that this was coming along and it sounded attractive.”

James Stagg, who project managed the build along with Richard Clampett, explains how Hamilton came about: “They had talked about a 100 footer and Magic Carpet had wanted to do a 100 footer for a while. Charles ultimately wanted to sail against other Wally owners, he wanted to join the class. He knew that this was coming along and it sounded attractive.”

Despite the number of boats Dunstone has owned, the latest Hamilton is surprisingly his first new build, the Carphone Warehouse boss having traditionally bought secondhand. He has also recently acquired the former Lord and Lady Docker classic 65m motoryacht Shemara, which for some 30 years was owned by property developer Harry Hyams (famous for Centre Point in London), who allegedly never used her. Shemara is now in refit at Trafalgar Wharf in Gosport.

Hamilton was put together in record time. When the first idea emerged for her back in August 2010, Magic Carpet was already in build (although this was stopped temporarily when Wally was in a financial hiatus last year). The 'go' button was pressed that October around the same time as the WallyCento rule was finalised. This ended up being slightly more modest than it started – Reichel Pugh were originally pressing for it to feature water ballast.

The first jobs were to complete a thorough weight study, while the Vrolijk office had until February 2011 to complete the lines.

According to Rolf Vrolijk the WallyCento design space is relatively big (on the water the boats will race under IRC), but as with all box rules, and particularly those for inshore racing, it pays to hit the maximum limits and be as fast as possible to be first into clear air and around the weather mark.

Therefore Hamilton is at the maximum in terms of mast height, sail area, beam, overall and waterline length and displacement, etc. Also unlike say a Mini Maxi, WallyCento racing is predominantly windward-leeward with some coastal and because of this, Vrolijk says they discounted twin rudders, even though the boat has substantial beam.

Structural engineering work was carried out by STRUCTeam on the Isle of Wight, and Hamilton has been built to Germanischer Lloyd requirements.

The rig, rigging and sails were handed by Southern Spars and North UK respectively. The mast is TPT, which when it was commissioned was the biggest Southern had made using their state of the art technology. Their sail maker is Kevin George, as well as Cup veteran Mike Schreiber, who worked alongside Rolf Vrolijk at Alinghi and is now with Luna Rossa. “We did a study on headboard length and also the balance of the boat, rudder position, position of the mast,” says Stagg.

While Wally usually offer their own designs for the general arrangement, for Hamilton Dunstone wanted his own and Design Unlimited was commissioned to come up with the interior while the build-work carried out by Struik and Hamerslag in Fakenham. Several alternatives were conjured up in order that one might be approved by Wally.

One of the big issues over the design was freeboard, Vrolijk wanting to keep it low while having to comply with Wally’s headroom requirements for the interior.

At Green Marine, Hamilton was one of the first builds at the company’s new facility in Hythe, built from scratch with female tooling (ie no plug was made). The construction was in carbon with all manner of core materials, including both paper and Kevlar Nomex with solid foam in the slamming areas. Work began in mid-February 2011, the boat emerging from the shed in June 2012.

“Rán [the 72] was nine months and this was probably 16,” say Stagg of the build time. “This is such a big boat - the whole surface area when we are fairing it is 2¾ times the size of Rán’s. “We faired and painted it upside down – so with a race boat mentality.”

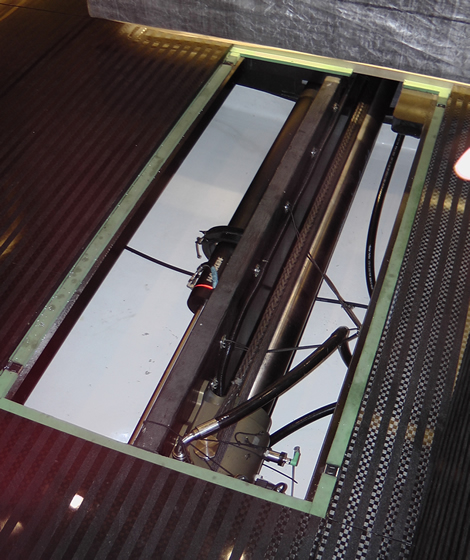

Other Wally requirements were keeping the deck clean wherever possible. As a result the majority of lines run below decks. Aside from Highland Fling, runners are otherwise a new concept for Wallys which typically have a backstay. Both the runners and mainsheet are operated by Cariboni Magic Trims. “They are like a double action ram, a 1:2 at one end and a 1:4 at the other,” explains Stagg. “We have got a sheave system below, one end is on the Magic Trim and the other end comes to the winch. So that is our fail safe. Obviously the big difference is you have got to get the runners forward, unlike your backstays, so even to hoist your mainsail we have got to do that. We needed a bare end to undo.”

Lifting keel

Central to the concept is the lifting keel, allowing the impressive draft of 6.2m. Judel-Vrolijk have fitted them on several race boats in recent history from Dan Meyers’ Numbers to the STP 65s Luna Rossa and Container.

“You have extra structure and weight, but for these boats it is a must,” says Vrolijk, “otherwise they can’t get into harbours.”

The keel was manufactured by APM in Italy, which has supplied other Wallys as well as Hetairos’ monster (where the keel and foil alone weigh twice Hamilton’s all-up displacement). While APM have an off-the-shelf design, some optimisation work was carried out on Hamilton’s fin and rams to remove weight, however Vrolijk points that the lift keel requires substantially more structure. “One day you will hit a rock and you had better make sure it is solid and maybe the bulb falls off but the rest of the structure can handle it. That is what we did with the STPs.”

The top of the keel foil has a square section and at the keel exit there is a carbon fibre fairing plate to fill the void around the foil when it is hoisted.

Bulb weight is a closely guarded secret, however Stagg says that their aim was to get more than 50% of Hamilton’s all-up weight into the keel package. “Most cruising boats are 30-40%, whereas most race boats are about 70%.”

Sails

The majority of sails on board at 3Di, save for a couple that are 3DL while the A3 is Cuben. Stagg says that at present the inventory is a work in progress. “We are doing coastal racing and windward-leeward, but we didn’t know what percentage of each we’d have in a season.”

In addition to the A3, the wardrobe includes masthead and fractional Code 0s, A1, A2 and A4, three jibs, a staysail and the usual safety sails. “It is a quite big inventory,” admits Stagg. “But because Magic Carpet hadn’t launched, we needed to sail by ourselves and do some data logging to try to learn as much as we could from this season before we sail with them at PalmaVela [in 2013].”

To help them get up to speed with the sails and rig tune they use a VSPARS system to monitor all that goes on aloft. “The sail budget on these things is up there so putting a camera system on is a very very small percentage of one sail. People say ‘it’s a bit Americas Cuppy’, but it is not really,” says Stagg. “You do need someone who can use it and we are fortunate we have got a couple of people who can. By the end of this year we will have a clear feel for where we are with the rig after only two events.”

Standing rigging is continuous EC6, while the 1+km of running rigging was speced and set up by Mark Thomas and Jonathan Taylor’s company, TT Rigging. Thomas sails on board manning the runners.

Walk through

Upfront, there is a Reckmann furler, another item there for Wally compliancy. “That was one of the things we kind of disagreed with Wally on,” says Stagg, “because we thought this was a way too powerful rig to be cruising with under full jib and full main, we came up with a delivery combination we wanted to use.” For this they have a smaller furling Solent jib that is self tacking system, via a dished track mounted in a concave well, immediately forward of the mast.

So the racing headsails are on hanks. “Under the Wally rule you must have a furler, but when you do an event you don’t have to have a swivel on the top. I think they were trying to encourage us to have carbon lightweight foils,” says Stagg. “But with these sails and all of the gybing, you would just go through a foil every week...”

The headstay is adjustable providing 1-3° variation in rake, although they are not rated to change this while racing. The headstay’s maximum working load is 23 tonnes.

Hamilton is fitted with Southern halyards locks on almost all sails save the storm jib. Plus, rather cutely, for night time use they have lock lights indicating whether or not each is engaged.

For the tack lines they have both 2:1 and 4:1 purchases led below deck, plus there is a lock strop. The 2:1 is used for the kites (flown off the bowsprit) and when more grunt is needed for the tight luffed sails, the 4:1 is used.

The mast step is very clean with all the lines coming down from the mast disappearing through apertures in the deck with the turning blocks hidden. From there they are piped back to the cockpit. Either side are the athwartships headsail sheet tracks with the up-down leading forward to a purchase (VO70 style) and the in-out on a ram.

Coming out of the companionway there is a guest’s seating area with the cockpit aft of this, right at the back of the boat. While the pit area is split in two either side, immediately aft of it, there are otherwise no visible lines anywhere near the guest’s area.

Being a Wally, Hamilton is obviously all push-button. The hydraulics on board were conceived by C Designs, and in total runs to 30 functions. “That was one of the big things we went through first of all in terms of how we were going to drive it and what we wanted to do with it,” says Stagg. “There is a minimum generator capacity for the class, but we decided that we wanted to drive our hydraulics off the engine, so our engine does run the whole time and is controlled by a PLC unit.”

In the trimmers area the sail controls are mounted on the cockpit side, to prevent them being accidently stood on (which could have disastrous consequences). However the main sheet trimmer can also operate his sheet via a remote.

In the middle of the cockpit there is a standalone mount for the twin displays. These are used for navigation and also the systems, including functions like keel up-down, man overboard etc. “When we are cruising shorthanded you can do pretty much everything from here,” explains Stagg. “We didn’t want to go massive on this, but Charles wanted to have some screens - he likes to see where he is when he is cruising. So someone, typically Richie O’Farrell [Hamilton’s skipper] stays here and controls the furlers and the stay controls. He needs to be fairly central in case he needs to say his bit.”

There are additional displays for example for those manning the runners, indicating how far in or out the ram is, the load on it, headstay tension, etc.

The winch package is from Harken with the primaries four speed. 1130s are used for the runners and primaries, 1111s in the pit (the smallest on the boat) while the others are 1125s. While there is huge flexibility with this kind of gearing, setting the line speeds remains a work in progress. As Stagg explains: “We are at the point now where we have almost got too much line speed on the halyards. When we are getting the masthead chute up, the line is pretty much just landing on the back of the boat, you can’t manually tail it.”

Aft in the cockpit are two L-shaped carbon fibre struts which are the mounts for a table, fitted when cruising. Similarly, there is a removal arch on which a radar set and a compact satcom dome are mounted.

Interior

Down below, much of the spec and the fit out follow requirements of the Wally Cento rule, including for example, a TV and sound system. “We have speced it up to the minimum requirement and maybe have added one or two things,” says Stagg. “We have cameras on board so that you can record when you are racing.”

On the business side, this also extends to a minimum size for the generator and a VO70-style retractable drive for the main engine.

The companionway steps are a masterpiece in carbon fibre, dropping you down into the saloon area where there is a C-shaped lounge area close to the TV to port, and a dining area with drop-down table to starboard. The chart table is directly off to starboard of the companionway ahead of the galley.

The corridor forward to the cabins is offset to starboard to hide the massive carbon fibre case for the lifting keel. To give some idea of what a colossus it is, one tonne of carbon went just into the keelbox and its structure, including its substantial ‘grounding hoop’.

There are well appointed cabins off to the port and starboard and we particularly liked the carbon fibre detailing in the heads compartments.

Up forward is the master stateroom, with an aft-racing double bed. When we saw Hamilton she was in racing mode, the bed heavily covered as above it is the foredeck hatch. Dropline systems are prohibited but sails do get dropped down the forehatch, weather permitting, says Stagg.

The interior has two set of floorboards, both made in carbon, with more grippy and harder wearing ones installed when racing, while when not the cruising set is veneered with wood.

Crew-wise Hamilton is allowed to sail with 26 under Wally Cento rules or 29 under IRC. Typically the working crew is 21, allowing Dunstone to opportunity to bring some guests on board.

Numbers

Performance-wise it is still early days, however upwind Hamilton is hitting 12 knots. Due to her displacement she is not a planing machine, her top speed off the breeze is likely to be no more than 20 knots. “I would say under 15 knots your performance can be higher than a 72 or Highland Fling,” says Rolf Vrolijk. “The boat accelerates, she goes to 15-16 knots and then the next jump, to 18-20, is a lot and to get there you will need a lot of wind. Of course the 72s get up [ie plane] very easily and probably above 15-16 knots they will be faster downwind.”

Until Magic Carpet is launched next year, Hamilton to date has only lined up with ICAP Leopard, who she saw off at the Superyacht Cup in Cowes this summer.

“People do draw comparisons with Leopard and us, but they are very different briefs,” says Stagg. “This is a nice day boat, whereas Leopard was built for record breaking, offshore events, and has a canting keel, etc. We have almost identical dimensions otherwise, we have got a slightly bigger rig. We did the Superyacht Cup and that is probably the only time we will sail with her. It’s a shame.”

So will the WallyCento class succeed? At the time the rule was conceived there were a few other owners thinking of building 100 footers until the recession began to bite even them. The feeling is that if there are any other potential owners waiting in the wings, it won’t be until Hamilton and the new Reichel Pugh-designed Magic Carpet line up next year that they might press ahead.

Personally we think it is a shame that the WallyCentos haven’t followed Leopard’s example. Certainly boats such as this always retain their value better if they have a fully fledged interior and fit out, but who’s to say when this has to be fitted? A partially stripped out 35-40 tonne WallyCento would be a beautiful looking speed machine around the race track.

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in