Farr 400 - successor to the Farr 40?

Of the new generation 40 footers, the Farr 400 is something of a surprise. The boat looks very different to its successful but now 16 year old predecessor, the Farr 40. As well as aiming to be a successful round the cans one design, the Farr 400 seems likely to have some potential offshore (something few Farr 40s achieved) but one of the most significant features of her design is that the boat can both be trailed and squeezed into a standard 40ft container for relatively inexpensive shipping.

The design for the Farr 400 was commissioned by a third party, Dubai-based Premier Composite Technologies. Managing Director of PCT, Hannes Waimer, in the 1980s set up German composites company SpeedWave and followed this in the late 1990s with DK Yachts in Malaysia. DK was a licensed builder of the Mumm 30, Farr 40, Farr 52 and Farr 36, as well as marketing their own Mark Mills-designed DK46.

In 2006 Waimer founded Premier Composite Technologies in the UAE. Boat building is very much a sideline to their primary business, manufacturing architectural parts in composites. Significant projects have including the 27 sliding domes for the Holy Prophets Mosque and the Emirates Palace Dome in Abu Dhabi.

American Dee Smith (who gave us a tour of the boat – see the video below), and has been involved in the development of the Farr 400 has visited their facility. “They have over 1000 people working there and they go through huge amounts of composite materials, both carbon and polyester and epoxy, etc. They have a lot of old SP engineers working for them doing their stuff. So to do a boat like this ends up being quite cost effective, because they have the tooling - a five axis milling machine that is 28m long by 10m wide and 4m and it has been cutting 24/7 for five years. So the whole boat is designed and the files off are sent off to them and they press the button and a boat appears...”

A significant feature of the Farr 400 is that the brief from Premier Composite Technologies, following their experience in boats of this size with DK, was to make the new boat easily transportable.

“That was felt to be something of a hurdle for people who are trying to attend regattas from one end of Europe to the other,” explains Russell Bowler, Vice President of the Farr Yacht Design and the Annapolis design house’s engineering muscle. Following considerable research by the Farr office into the extremely varied regulations governing maximum dimensions for trailering in different countries, the Farr 400 can be trailed around Europe and most countries around the world, free from restriction. When it is heeled over on its cradle the boat also will fit into a flat bed container.

But as a result, despite its name implying otherwise, the boat is 38.7ft (11.8m) long and her max beam, at 3.42m, is 0.6m less than that of the Farr 40. Her mast can be split in two for transportation while the plate at the top of the keel fin (located immediately forward of the companionway) comes off, allowing the keel to be lifted up into the boat, reducing draft from 2.9m by just over 1m, while still being able to close the main hatch. According to Dee Smith the boat can go from cradle to water in just 30 minutes, compared to a Farr 40 where, after shipping, the keel has to be faired in again – a substantially longer process.

“The idea was to modernise that type of one design racing and it is focussed on being a one design. It is not focussed on IRC,” continues Dee Smith, who isn’t a fan of the RORC’s rating system. However the boat would appear to also have some potential offshore. Last year Smith sailed a Farr 400 in the Giraglia Rolex Cup from St Tropez to San Remo, Italy – a light air race where he says they stayed in touch with the TP52s ahead of them. “This would be a great Transpac boat, if you have some youngsters who want to have some fun. It is legal for Cat 2 racing. You might be able to get it to Cat 1.”

From a design perspective the hull shape reminds us of a scaled-down inshore version of the Abu Dhabi Ocean Racing VO70, which FYD also designed, with a chine at the stern – albeit less aggressive and extending from the stern only one third of the way forward – and considerable volume in the bow, as seems to be the latest trend in yacht design. Dee Smith is a fan of the substantial volume in the hull forward: “The full bow enables the boat to feel longer than it really is and also when you have a big back end and a chine, the normal tendency is that when the boat heels over, it kind of pumpkin seeds and the bow goes down. But on this boat you heel over and you stay level, so therefore it stays balanced and it is easier to steer the boat upwind. Everybody is just loving the balance of the boat. It is easy to keep it going. It is easy to push the bow hard and because it is narrow you don’t have to sail it flat.”

Slab sides, relatively high freeboard and less beam, plus a reverse camber to her foredeck give the Farr 400 a distinct look, not one that is as immediately attractive as the McConaghy 38 – we will avoid getting into analogies with women at this point. But certainly her looks grown on you and all of these features are of practical benefit.

Dee Smith recalls sailing the Farr 400 in 30 knots in San Francisco Bay last year. “It helps taking the spinnaker down – we had three guys go forward because it was windy and we were new to it, and you don’t have a problem with the boat going underwater.” And in the big conditions the boat performed exceptionally: “We hit 27 knots in 30 knots of breeze. It is fast and it performs well and it is dynamic and as people learn how to sail them they are going to get faster and faster.”

Russell Bowler points out that the added volume forward also helps counter the latest evolution in rigs that are getting more power with flat topped mains and more stretch resistant materials being used in both the sails and rigging. “I think over the last few years it has been shown that full bows do go upwind. Even in light airs and choppy weather they are a little more difficult but they are not too bad. With the powerful rig you can take the full bow upwind.”

The concave foredeck means there is more freeboard in the middle of the boat to lift the keel up within the cabin, while a secondary effect is making the deck stronger than it would be if it were flat.

Smith adds: “It would have been nice to be a little bit wider for IRC but there are benefits and paybacks. The ratings like beamy boats, but the water doesn’t. This boat, with the long keel and the big bulb, you can heel it over and use the bulb, whereas a boat that is really fat in the middle and pinched at the ends, like a Farr 40, you roll it over a degree too much and you stop. This makes it, I think, a little more kindly to owner drivers and crews that maybe aren’t really good, so it keeps the fleet together and obviously the good guys are still going to win, but they aren’t going to win by as much...”

In the 40ft size range at the moment, there is also currently the McConaghy 38, Ker 40 and Soto 40, but of these the Farr 400 feels most like a big boat that has been scaled down. This is partly due to her freeboard but also the deck layout and features such as the pedestal grinder (the only one of the four to have one) and the halyard lock on the jib.

As is the modern philosophy – like Russell Coutts has applied in the America’s Cup – the Farr 400 is designed so that it can be raced in anything from 5 to 30 knots of wind, while still providing close, dynamic competition.

“We wanted to make sure it went upwind well, so the boat has plenty of rocker in it and it is seakindly in waves and it has plenty of righting moment and it has plenty of sail area,” says Smith. In fact to improve the boat’s light air performance they added 4sqm to the mainsail.

But Smith adds that the Farr 400 shares another trend with the more sophisticated big brothers such as the TP52s in that the boat has different modes and this opens up the possibility of making more lanes available. “Therefore the racing ends up being closer while downwind it is almost as fast as a TP52. It is very powerful, fast and easy to sail and it is balanced. Because of that you don’t need a ton of people – eight or nine people can sail the boat well.”

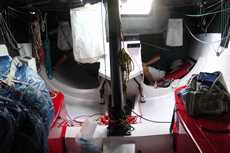

Down below Russell Bowler and his team have done a fine job on the engineering task. Most noticeable is that the chainplates don’t sit on their own bulkhead, but instead rely on local reinforcement, while there is a stringer running athwartships just aft of the mast for the headsail sheet tracks.

“There are only about six major parts,” says Bowler of how the Farr 400 is put together. “The fit between the pads is the best you have ever seen anywhere. It goes together really nicely because they took everything off milled tooling and they are infusing all the parts, so the whole thing is a big jump ahead in construction.” Construction is carbon fibre and epoxy with a foam core.

The boat has had a few modifications since it was first launched in Dubai a year ago. In addition to enlarging the mainsail, they have also added a fraction more rake (now around 4.5deg) and this has improved upwind performance, says Smith.

The T-shaped keel fin comprises a steel box section with a carbon fibre fairing around it, but these fairings were found not to be man enough and have since been replaced with a new design. “Now it is much better,” says Smith. “It is supposed to have 6-10% more lift in it with no more drag. The boats seem to be reacting the same now, which is perfect and I think there is more grip.”

For the Farr 400’s future as a one design, the weights of the boats are coming out very close with the fins and bulbs (milled by Premier Composite Technologies in house) coming in within 2kg, while the Southern Spars masts are within 1.5kg. The milled tooling also helps boats remain as near identical as possible.

Sails are down to each individual owner and at Key West Race Week last month, four of the five Farr 400s had 3Di wardrobes from North, while the fifth was with Quantum. “We try to make them very simple,” says Dee Smith of the sail restrictions. “We don’t want you to have to shrink spinnakers so the spinnakers have two measurements a foot measurement and a mid girth both a minimum and a maximum. That way people won’t push too hard and worry because nylon is nylon. Same on the jibs and mains.”

To date nine Farr 400s have been built with the latest heading for former Farr 40 owner and CYCA Commodore, Australian Matt Allen. Other owners to date have come from Farr 40 and Farr 36 classes. At the time of writing PCT had orders to build five more.

Vital statistics:

| Column1 | ft | m |

| LOA | 38.71 | 11.8 |

| DWL | 36.45 | 11.11 |

| BEAM (max) | 11.22 | 3.42 |

| DRAFT (down/up) | 9.51/6.5 | 2.9/1.98 |

| DISPLACEMENT | 9105lb | 4130kg |

| BALLAST | lb | 2464kg |

| Sails: | ||

| I | 51.18 | 15.6 |

| J | 14.6 | 4.45 |

| P | 52.99 | 16.15 |

| E | 19.03 | 5.8 |

| STL | 22.38 | 6.82 |

| Sail Area Upwind | 1098sqft | 102sqm |

| Sail Area Downwind | 2530sqft | 235sqm |

In the video below Dee Smith takes us on a guided tour of the Farr 400 and we finish off with some footage from on board Joe Woods' Red at Quantum Key West Race Week.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in