Iain Murray's America's Cup update

Iain Murray, Regatta Director for the 34th America’s Cup and CEO of America’s Cup Race Management last night brought us up to date with the latest from Cup-land.

When he spoke, Murray, a yacht designer by trade, was dabbling with how the revised branding was going to look on the AC45s now that the first boats – Emirates Team New Zealand and Luna Rossa – have been fitted with wing extensions. These add an extra 4m to the 21.5m AC45 wing's air draft, or an additional 8sqm onto the existing 85sqm.

Following these initial trials that it sounds like sailing with the extension fitted is likely to be the norm, with their only being taken off on extra-breezy days.

“It is fair to say that we probably ended up sailing in more wind than we envisaged,” said Murray of the ETNZ/Luna Rossa trials that have been taking place off Auckland over the course of the last two weeks. “The feedback from the crews is that they didn’t notice having the extra sail area up there. All went well and the testing of the TV equipment on both of those boats went according to plan and we experienced no difficulties. We had a slight incident with one of the transformers with the 3GHz RF signal that we will sort out.”

Murray says that they were sailing in up to 18-20 knots in flat water with the enlarged wings and there were no structural issues.

The reason the wing extensions were introduced was due to the America’s Cup World Series visiting Venice in May this year where conditions are expected to be very light.

“Our target was to get the boats to lift hulls in 5 knots of wind upwind and downwind,” said Murray, who adds that without the extension, hull flying typically occurs in 7-8 knots. “So to do that we would need a combination of less weight on the boats – but obviously the wing extension adds weight - and increase the horsepower with sail area. So we have added the horsepower and sail area, and where we go on the diet part is the next thing.”

Weight reduction might include reappraising some of the considerable media equipment that each boat carries and whether it is all vital. Another option is whether or not teams would be prepared to sail with less crew if they ever have to race in 5 knots of wind. “All those things are possibilities, but it is just one thing at a time,” says Murray. “We have done the hardware part – now we can look at the rest.”

In terms of the usability of fitting the extension, they have had to move the jammer for the spinnaker halyard to the foot of the mast on the AC45, while all the masthead electronics, such as the various antenna used to be beam video back from on board, has remained on the existing masthead with the extension fitting on top, encasing it.

“Putting it inside something, there is the potential for transmission issues particularly with all the carbon fibre around it," says Murray of the masthead gear. "And also the heat – so we wanted to test both those things and that went well. Now, because we don’t have to remove any of the electronic equipment, etc - that can stay on and the wing extension just bolts on and off - we think to take the extension off is probably half an hour [of work] once the wing is down on the ground.”

Currently AC45 hull no15 is under construction while no16 is due to be starting soon.

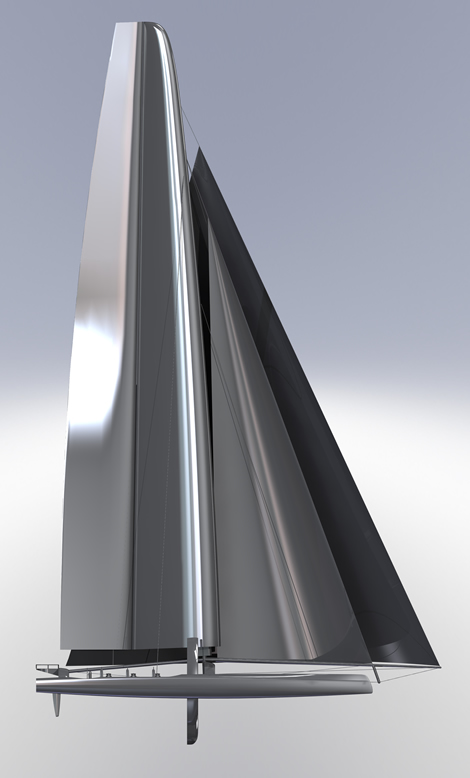

AC72s

For the America’s Cup crews it is going to be an immense task to get their ultra-speedy AC72s around the confined race track in San Francisco in what is likely to be substantial wind on the Bay.

Murray highlights this: “To race these boats on the course, we are talking about a minimum of six or seven tacks up a beat and to gybe one of these things – unless they can come up with something fancy like removing the forestay, which is a hairy thought – to unfurl the downwind sail, set it, retrieve it and go around the bottom mark all in the space of six minutes over three miles, is a pretty scary thought. You put that into a race with all the tacks and bits and pieces and the duration of the race, and what has got to be done, they are going to be some athletes these guys.

“As I know only too well sailing a 12m - we saw a lot of good crews in Fremantle, but there was still all sorts of drama - to get the crew work between 11 people to run like clockwork doesn’t come overnight. We spent years in Fremantle doing it. And on these boats things are happening at four times the speed they were on a 12m. So with the aerobic and the physiological and the skill sets and acrobatics and crew work - I think it is gone to a level that sailing has never seen before. It is not that the jobs are any different, it is more the speed it all happens at and the loads generated by the boats. There is no rest. The guys constantly have very high heart rates just to physically do the jobs in the time period required. I think that has really crept up on people.

Murray adds that another eye opener has been the complexity of the wings. "There are probably more moving parts and these things can be as simple or as complicated as people want to make them - both the design and the way you make them. We worked with Southern Spars and North Sails in developing our joint design and there were options varying in manufacturing times by a factor of three!”

As a result there is not only a cost implication in building a more complicated wing, but also will the crews, in the heat of the moment, be able to use all the features of an ultra-tweaky wing?

“I know with our design we shied away from that because the complication and cost of doing that compounds at a big rate," Murray continues. "To try and keep it simple with this America’s Cup and sailing these boats in San Francisco in all this wind on very tight courses and having to do all the manoeuvres and bits and pieces - you have to ask yourself what is the priority? Getting around the course at 99%. You might have all the complications and controls in the world, but if you have got no one to operate them, or to have their head in any sensible territory to use them, they are of no use to you. I think that is what all the teams are working their way through.”

Contemplating this further, Murray discussed the crew roles on board. For example the ACRM design package AC72 features three pedestals on each hull. In an 11-strong crew on the AC72 with six grinding, that leaves one steering, another operating the pit and three manning the sheets – so there are no spare hands.

“It is not dissimilar to what’s gone on in the past where you had six people on pedestals grinding at maximum output. How they are linked together will probably vary from boat to boat. But it is fair to say in a gybe which is furling and unfurling, and going around the bottom mark and hoisting the spinnaker, you will see probably all six people grinding and it is going to be hard work. There are going to be various places on the course where the horsepower requirement is substantial. It is going to start coming into the windward mark, where you are going to have to hoist the downwind sail. There will be this huge apparent wind, and heavy sails, big sails and that is just the beginning of going downwind. Sailing into the wind will be the recovery period.”

Murray says that it is not out of the question, if there is enough drive from the teams, that they might look at putting more crew on board the AC72s. “Let the boats go sailing. If we need to add a few people, we’ll talk about it. What is important to me is that we run good close races. We don’t want catastrophies at marks.”

Given the crew weight limit, Murray said it was interesting to encounter America’s Cup grinder Mark McTeague in San Diego. “He has been the grinder of choice on the ACC boats for many years. He used to be 115-118kg of ultimate strength and he was flaunting his new body to the teams in San Diego at 95kg. I think that is a good indication of where it is going.”

So who has bought the design package? At present it seems that only Oracle Racing have, however Murray says that the package is with three other teams who are taking to their builders to have it costs and these teams do have a “financial commitment” with ACRM. “It is fair to say that I think to be clear there is probably three pretty firm on it. And there are others that are less firm. I think the other teams have been possibly been talking to [other] people as well. After Team New Zealand’s effort with Luna Rossa, it is has been felt that that wasn’t a bad idea.”

In terms of a deadline for building, Murray says that they set the June entry deadline because that was when they reckoned it would be the latest to start building. In reality, he acknowledges, that it could be pushed.

“It really depends on how the boat is built and how much you are going to break it up. We are seeing Luna Rossa building hulls in Italy and a fair swag of non-Deed of Gift parts (ie not the hulls) in New Zealand. They are utilising labour all over the world and a large part of it is in the wing. If you were going to buy an off the shelf Southern Spars package, that is a great part of the responsibility moved to one side. So you could do it in six months and that means you could in theory leave it until October or November but you would have very little sailing time and the main players are pretty keen to get on the water to see what they have got, because we all know time on the water is critical.”

In terms of the hours likely to go into building an AC72, it is case of how long is a piece of string. Murray has been quoted 15,000 man hours by Southern Spars to build a wing while another quote has come in at 25,000 man hours for the platform. “If I was running a team again I’d like to start in May and would allow myself eight months.”

Louis Vuitton Cup race formats

At the moment with just three challengers – Emirates Team New Zealand, Artemis Racing and Luna Rossa, there is much debate going on about race formats for the challenger selection series.

Murray stresses that regardless of the number of challengers the sailing period will not be shortened. Since the last Competitor Forum meeting in Auckland they have been working through all the different options, race formats and various drafts of the points scoring, to see how it could work with different numbers of challengers.

“The thing to come out of it is that they are not going to have much time to spare in San Francisco. The program from 4 July through to the end of the America’s Cup in September to is going to be very very busy when you put in a Youth Championship, the Louis Vuitton Cup, the opening weekend on 4 July, etc. John Craig and the race committee are going to have long days on the water and very few days off in that nine week period.”

The challengers have had a say in this, says Murray. “Certainly I have models where teams do get rested. It will depend on how many races we run. If you have had a look at the original format there was an exceptionally small amount of time between series and the teams have said that is too fine. In the old days they had quite big breaks to make modifications. With the changes this time around – we don’t have keel, and the hulls are probably a smaller part of the speed equation so it will more be wings or centreboards or sailing techniques or sails, so the changes will be a lot quicker to happen. But it is just something we are going to have to happen and revisit it with the teams when we know how many we have got and see how long they want.”

There is also discussions about the possibility of teams that are not able to step up from an AC45 to an AC72 being able to have their own racing in San Francisco around the time of the America’s Cup. “There has been some talk about that and we will talk about that,” says Murray.

Latest Comments

Add a comment - Members log in