New membrane sail technology

Tuesday January 20th 2009, Author: James Pleasance, Location: United Kingdom

Danish sail maker Elvstrøm Sails has launched their revolutionary new EPEX technology, on display at the Düsseldorf Boat Show this week.

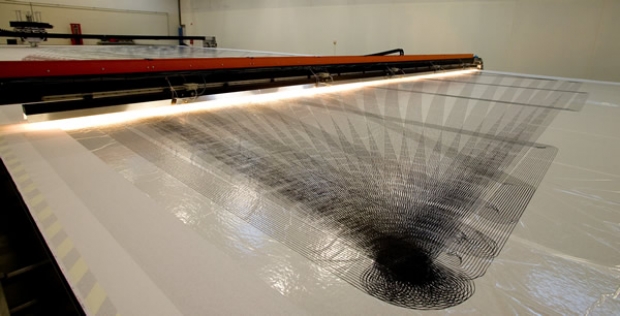

Representing a breakthrough in modern sail making technology, EPEX is the name given to a unique process of bonding membrane sails using a high pressure vacuum system, instead of traditional heat rollers used in most sail making factories around the world.

Following three years of intensive design and research, the company has built a new 2,000sqm loft facility at its headquarters in Aabenraa, Denmark to house the impressive EPEX vacuum bed on which the membranes are produced before being finished in an adjacent loft. To create the EPEX membranes, Robotic gantries hold the membrane films to the bed and lay the yarns across the full width of the bed as a 0.8 bar vacuum creates a 0.8 bar pressure to cure the laminate. The vacuum also acts as an extraction system in its own right avoiding the need for overhead ducting.

As Elvstrøm Sails Design Director Andrew Smith explains: "The traditional system of curing sail membranes by using heated rollers on a bed or airframe can cause the yarns to crush under pressure and leave gaps or voids between the yarns. This is the primary cause of delamination in sails. The EPEX system, on the other hand, applies a very high pressure through a vacuum which creates void free laminates which are uniformly pressured on the vacuum bed for a predetermined time. The result is a far stronger bond to the membrane which makes the sail last much longer without the risk of voids”.

The first EPEX sails were produced last summer and tested rigorously on a racing 40 footer, and a cruising 35 footer with furling and reefing systems. After many miles and hours of use, the laminate remained perfect. Even after testing with a short curing process, the membranes have produced the same results, proving the success of the technology.

“We are delighted with the results of EPEX” commented Jesper Bank, Commercial Director. “At Elvstrøm Sails, we pride ourselves on constantly developing our design and technology processes. EPEX has set a new benchmark in the way produce sails and we look forward to showing the technology to our customers at Düsseldorf - we have even built a bridge of EPEX membrane on our stand which visitors can walk over to see the strength of the product for themselves”.

Latest Comments

Add a comment - Members log in