200 new moths

Tuesday May 30th 2006, Author: Media Release, Location: United Kingdom

The International Moth has received a lot of attention recently in the sailing press, and the exposure this radical boat attracted during the Melbourne stopover of the Volvo 70 race seems to have pushed interest up another notch or two.

Despite the high demand, fleet sizes have not increased dramatically due to the limited production capacity of the existing boatbuilders. The combined capacity of the two leading suppliers of International Moths, Fastacraft in Western Australia and Full Force Boats in the UK, is little more than 30 boats per year, with delivery times being quoted up to 12 months on new boats. This is all about to change following the announcement that Australian boatbuilder KA Sail have commenced volume production of their new Bladerider hydrofoil Moth in China.

Andrew McDougall, Managing Director of KA Sail, has had a long association with the Moth and has drawn heavily on his experience as an international competitor, sailmaker, designer and boatbuilder to create the Bladerider. In August 2005, McDougall brought in successful Melbourne business man Michael McAuley to develop and implement a plan to expand his sailmaking business to build boats in the numbers needed to satisfy the explosion in demand. This has entailed building a professional business management, engineering design and production control team, and the implementation of the latest e-business technologies needed to support the expanded business.

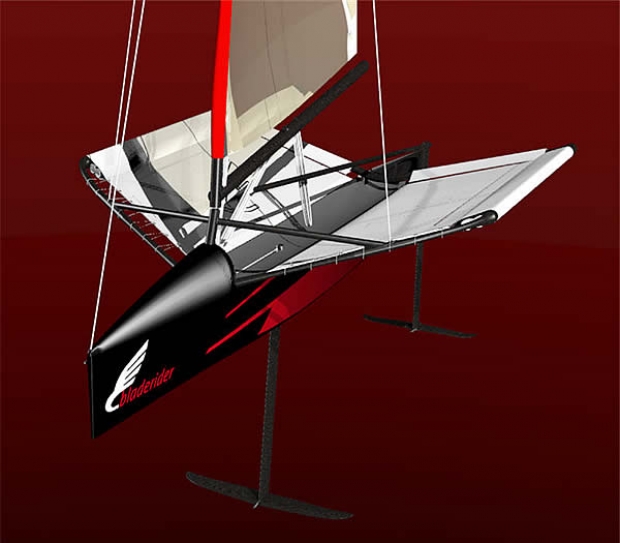

McDougall design sails have dominated the International Moth race scene for several years. The challenge was to apply this same design skill to create a faster, lighter and easier-to-sail boat. McDougall opted for a lower foredeck and freeboard similar to that of the Full Force Boats made in the UK, but unlike the UK boats, the Bladerider has volume in the stern for buoyancy when tacking in difficult conditions. McDougall has also modified the hull shape to give improved performance in sub-foiling conditions, optimized for a boat speed range of two to six knots. The finer bow and flatter, squarer and straighter mid/aft sections are designed to assist hydrofoil lift-off.

The hydrofoils and lift controls have also been redesigned to allow the boat to lift easier out of the water. After extensive computer modeling and testing, McDougall zeroed in on a foil optimized for hydrofoiling speeds in the range of six to 25 knots. The foil design has a slight curve and twist with elevated tips, similar to a modern aircraft wing shape. Lift on the main foil is controlled by an offset wand at the bow of the boat, but unlike other wands, the Bladerider uses a different gearing that maintains constant lift during the initial stages of lift-off, and maximizes feedback when the boat is at the correct ride height. The end result is an almost automatic lift-off and flight, with minimal corrections required by the skipper. It’s not perfect, but it’s close.

The rig on the Bladerider consists of a KA 8m sail and 100% carbon mast and boom. A larger 9m sail is also available. Although Moth class rules limits the sail area to 8m, KA has produced the larger sail in response to demand from current Moth sailors looking for more speed. Other changes you will find on the Bladerider are the aerodynamic molded carbon-fibre wing frames and a new mast stump arrangement designed for easier vang, outhaul and downhaul adjustments.

Perhaps one of the most remarkable aspects of the Bladerider is the weight and ease with which the boat can be transported. By using 100% carbon fibre construction, the weight of the hull has been kept under 10kg, and when fully rigged the boat still comes in under 30kg. The Bladerider can be dismantled and packed away in a compact travel case, which can be transported on roof-racks, eliminating that troublesome trailer. The lightweight and compact size of the Bladerider travel case is a boon to interstate and international competitors, who can now cost-effectively airfreight their boat anywhere around the country or the globe.

The Bladerider is manufactured by JinLi Composites, China’s leading fabricator of advanced composites components with deliveries of the new boat commencing in July at a planned production rate of 200 boats a year. There is rumoured to be some support for the Bladerider to take a spot in the 2012 Olympics. KA Sail have obviously taken this into consideration in their selection of manufacturing facilities as JinLi certainly has the capacity to push production well above 1000 boats a year. Whatever the ISAF and IOC equipment committees decide, the future of this radical and exciting new boat seems assured.

Latest Comments

Add a comment - Members log in